BLOG

PrecisionCraft 3D: Rings Jewelry Printing Redefined

PrecisionCraft 3D: Rings Jewelry Printing Redefined

What is PrecisionCraft 3D?

Imagine designing a piece jewelry that is so precise and complex, it feels like magic, but it’s not. This is PrecisionCraft 3D, an innovative technology that is revolutionizing the way we make high-end jewelry. It’s about printing high-resolution 3D to create detailed, custom jewelry items with unmatched speed and precision.

The Evolution of Jewelry Design

Jewelry making has evolved a great deal from carving wax molds by hand to creating using the mouse. This transition of the bench into the screen hasn’t just increased the speed of production but opened up a new realm of innovation. PrecisionCraft 3D is the culmination of this evolution.

How 3D Printing is Transforming Jewelry

From Traditional to Digital

Before, making one ring could take weeks or months. Nowadays, thanks to 3D printing, designers can go from concept to prototype in a matter of hours. The digital workflow reduces manual mistakes and creates complex designs that were previously difficult to achieve.

Benefits of 3D Printing for Jewelers

Speed and Accuracy

PrecisionCraft 3D drastically reduces lead time. Jewelers can move from CAD to final mold in a matter of hours, with precision of micrometers.

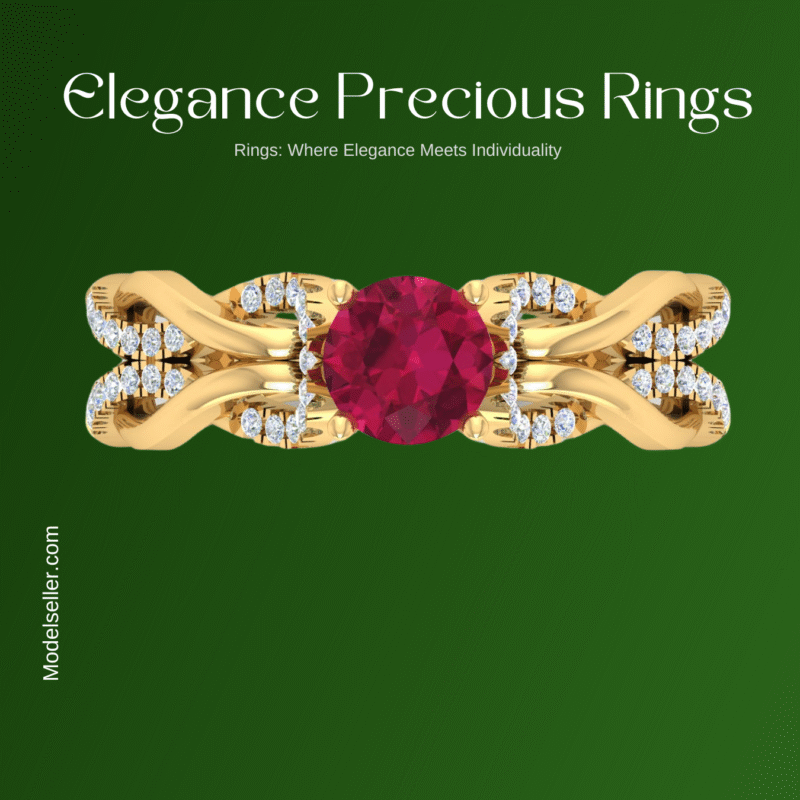

Limitless Customization

Do you want your initials to be engraved on the wedding band? A ring with the shape of the shape of a dragon wrapped on your finger? 3D printing isn’t limited to this; it thrives off.

Cost Efficiency

Don’t waste any more materials. Layer-by-layer technology ensures that every drop of metal gets employed for a purpose and is a cost-effective method of saving money for prototyping as well as production.

Inside the PrecisionCraft 3D Process

Design Software Integration

The process begins with software. Typically, this is tools for CAD such as Rhino, MatrixGold, or ZBrush. Designers design detailed 3D models, detailing every curve and detail.

Material Selection and Technology

PrecisionCraft 3D supports various printing techniques, from to (Stereolithography) to DLP (Digital Light Processing), using materials such as castable resin, or wax-like polymers that are burned out using the traditional lost-wax casting process.

Layer-by-Layer Perfection

After the file is completed when the file is ready, the printer creates the model using extremely thin layers. The resolution is so high that it is able to recreate details as precise as stone or lace.

Why Jewelers are Choosing PrecisionCraft 3D

Precision Like Never Before

With a resolution as low as 10-microns resolution, PrecisionCraft 3D delivers detail that human hands simply cannot duplicate.

Bringing Ideas to Life Faster

Speed is the key word in the business. From customized client demands to seasonal launches of products Jewelers can provide their services quickly and efficiently.

Seamless Prototyping and Production

Are you looking to test a new concept? Print it. There’s no need for costly molds or equipment until you’re ready to go into production.

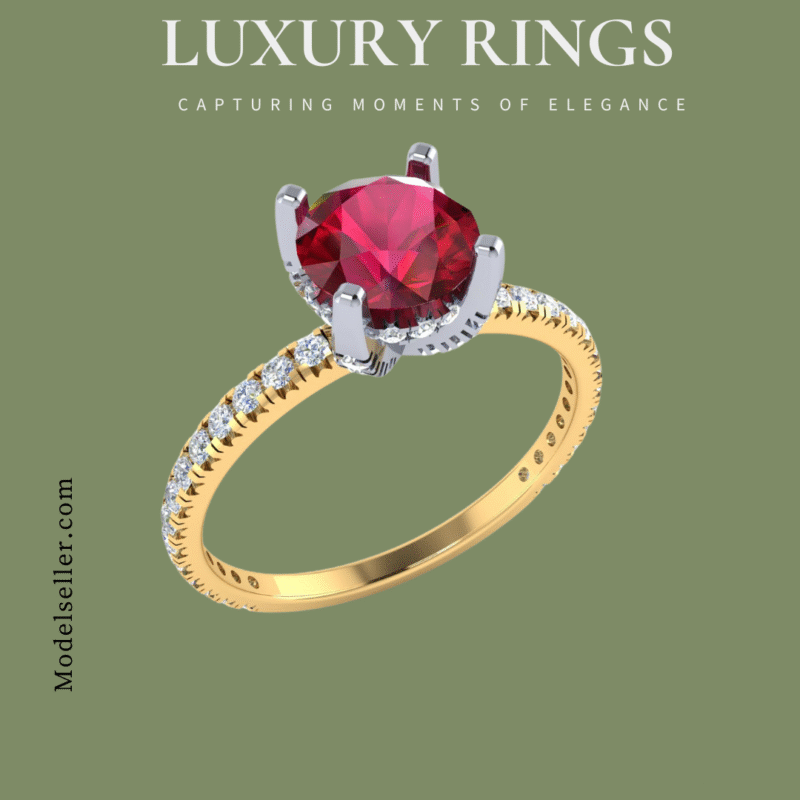

Customization is the New Luxury

Personalized Engagement Rings and Heirlooms

We live in an age of personalization. People are looking to have their love stories culture, their own uniqueness, and even their personal stories included in the jewelry they wear. 3D printing can make this happen with a minimum of effort.

Catering to Niche Markets

If it’s Viking-themed rings LGBTQand inspired pendants or cultural talismans PrecisionCraft 3D gives designers the possibility of serving a range of market segments without a huge cost.

Sustainability in Jewelry Manufacturing

Reduced Waste by 3D Printing

The traditional process of making jewelry wastes a large quantity of metal. 3D printing however utilizes only what it requires–no more, not less.

Ethical Sourcing and Smart Design

Many eco-conscious brands are using ethically-sourced metals in conjunction with 3D-printed molds to create eco-friendly high-end.

Industry Use Cases of PrecisionCraft 3D

Independent Designers

Indie and startup creators do not require deep pockets to get into the jewelry business. Anyone equipped with a printer and laptop can create their own collection.

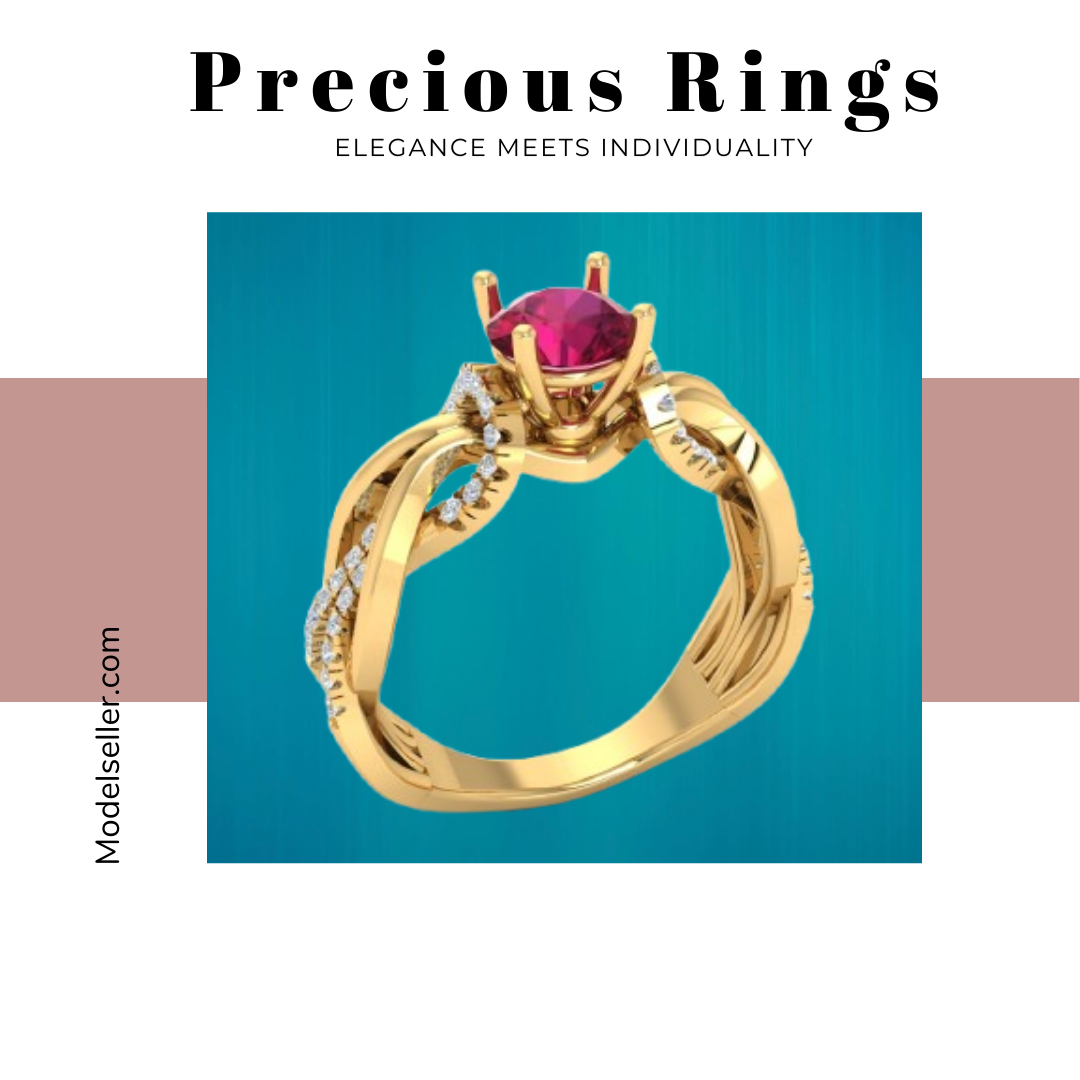

High-End Luxury Brands

Prestige brands are employing PrecisionCraft 3D to offer ultra-custom items for their VIP customers. Think exclusive brooches with diamonds or avant-garde settings.

Mass Customization Retailers

Brands such as Etsy sellers, or fashion jewelers of the mid-tier use 3D printing for mass-production of customized pieces on a large scale.

Challenges and Limitations

Material Constraints

Although they are growing, the material choices remain limited in comparison to traditional metal fabrication. Silver, gold and platinum are still in need of casting. 3D printers are used to handle the wax/resin stage.

Skill Gap in CAD and Printing

There are many jewelers who are not expert in software. Understanding 3D design tools as well as maintenance for printers can be a hurdle.

It’s the Future of Jewelry with PrecisionCraft 3D

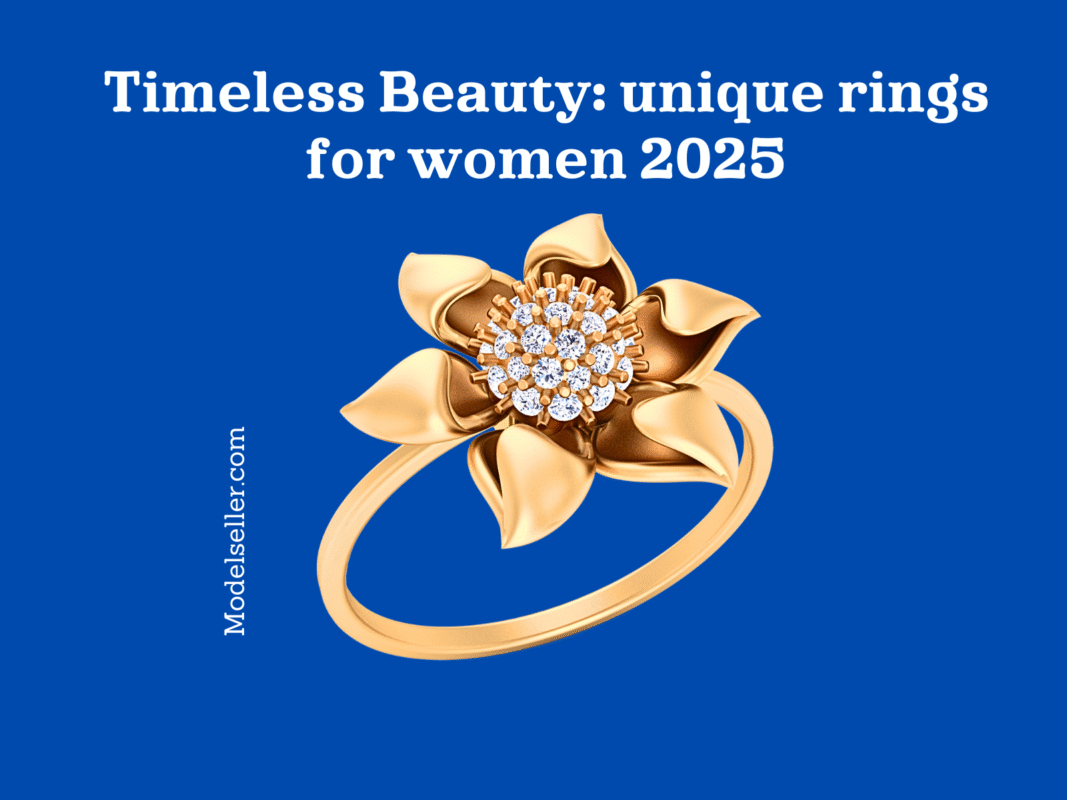

AI-Powered Design

Imagine feeding a request into an AI–“Design me a flower ring for the summer wedding”–and you’ll have a printed STL file. This is where we’re going.

Advanced Materials and Finishes

From diamond-infused composites, novel materials are being developed every day.

Global Accessibility

Soon everyone with a dream and an printer, regardless of where they reside, will be able make world-class jewelry and send it to the world.

How to Begin using PrecisionCraft 3D

Software Tools and Training

Start by studying CAD tools such as Blender, Rhino, or MatrixGold. There are plenty of absolutely free YouTube tutorials as well as paid classes.

Choosing the Right Printer

Find printers designed specifically for jewelry. Brands such as Formlabs, B9Creator, and Solidscape offer customized solutions.

Working with the right Service Provider

Are you not yet willing to spend money on equipment? Work with 3D printing firms which specialize in casting jewelry molds and casting.

Conclusion

PrecisionCraft 3D is more than an innovative tool, it’s an amazing advancement. It’s breaking down the walls between imagination and creativity. It doesn’t matter if you’re a creator, an organization, or an artist with a sketchbook the 3D printer is your way to create magic. It’s not only the future of jewelry, it’s the present.

FAQs

1. How long will it last? 3D jewellery that is printed?

Molds 3D-printed are generally used to create castings of metal, which is whyu.